Concrete.ai has announced the commercial launch of Concrete Copilot, an artificial intelligence platform programmed to generate concrete mix designs and predict hardened matrix performance within seconds. During extensive field testing with producers across the U.S., the program optimized mix designs used in over 2 million cubic yards of concrete. The average material savings were $5.04/yard, and the average carbon reduction was 30 percent. The positive trending metrics were typically observed within a month of Concrete Copilot deployment.

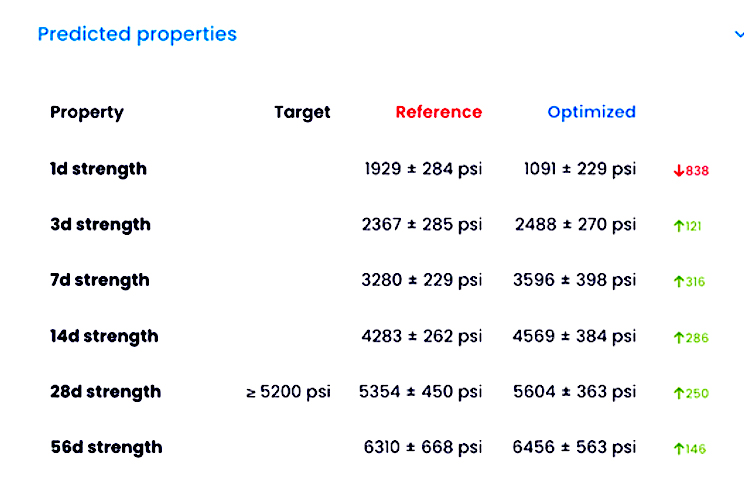

Concrete Copilot equips producers to compare the likely results of mix designs selected on traditional criteria versus artificial intelligence-powered methods.

The program first integrates with a producer’s present and historical mix data. Producers can select optimization criteria based on their specific objectives. Concrete Copilot then creates millions of mix designs in seconds and presents the optimal one to the user to approve or modify based on their judgment and experience—streamlining to minutes a process previously entailing months. The platform uses data on materials in a current supply chain; when there are shifts in a material’s availability or cost, producers can rapidly create new mix designs. Concrete Copilot also allows for quick evaluation of the sustainable concrete mix materials entering the market each year, helping them to enter commercial production quickly for an immediate environmental impact.

“I’ve spent 26 years working in the construction and ready mix industries and personally know the challenges concrete producers have to overcome to find the most economically viable mix designs,” says Concrete.ai CEO Alex Hall. “We built Concrete Copilot so producers don’t have to choose between cutting cost and carbon. Our ultimate goal is to reduce the annual global carbon footprint of concrete by ~500 million tons just by optimizing concrete mixes with materials already in supply chains.”

“Integrating Concrete Copilot into our existing software was a quick and smooth process. Using our own data and local materials, the tool efficiently streamlined our mix design process, allowing us to maximize materials cost savings and deploy the optimized mix designs into production faster,” adds Chris Rapp, vice president and general manager of Illinois-based VCNA Prairie Materials. “This resulted in significant reductions in cost and carbon footprint.”